How to increase shrimp growth effectively in nursery culture?

Aquaculture production has grown enormously in recent years and Penaeid shrimps are one of the most important cultured species worldwide, especially in Asia, due to their high economic value and export.

The brackish water is pumped into the pond through fine filtration systems up to a depth of 3-4 feet. The water is treated with chlorine at 20 ppm-30 ppm and left for one week. The pond water is also treated with minerals and probiotic yeasts before stocking.

Biosecurity: certain biosecurity measures are carried out like bird netting, crab fencing etc, but most farms lack proper biosecurity.

Stocking: quality L. vannamei post-larvae pl12 – PL16 are procured from shrimp hatcheries after quality and PCR tests. The post-larvae are transported from hatcheries to culture ponds by road and air, and should only be stocked after a proper acclimatisation process.

Stocking density: The stocking density of shrimp post-larvae is usually in the range of 70-100/m2 but can be as high as 120-150/m2.

| Sl.no | Particulars | % |

|---|---|---|

| 1 | Present Culture of Vannamei: Shrimps | 90% |

| Black tiger shrimps | 10% | |

| 2 | Normal pond from Brakish water areas | 40% |

| Earthen ponds converted from paddy fields | 60% | |

| 3 | Farm Size: Below 0.1 - 0.3 Ha | 75% |

| Above 0.3 Ha - 0.8 Ha | 20% | |

| Above 0.8 Ha | 5% | |

| 4 | 1-2 no of ponds / Farm / Person: | 60% |

| 3-5 no of ponds / Farm / Person: | 10% | |

| Above 5 no of ponds / Farm / Person: | 10% | |

| 5 | Above 8 Year old ponds | 35% |

| 5-8 year old ponds | 30% | |

| 2-4 year old ponds | 20% | |

| 1- year old ponds / newly pond | 15% | |

| 6 | Single inlet or outlet system | 15% |

| Separate inlet and outlet system | 10% | |

| No provision of inlet and outlet system | 10% | |

| 7 | Pumping water by Diesel Pumps | 70% |

| Pumping water by Electricity Pumps | 30% |

Feeding: all farms use formulated commercial pellets for routine feeding purposes. Most use a combination of broadcasting and check tray methods as feeding strategies, adjusting the levels regularly according to observations. On the whole they are fed four times a day, according to the recommendations of individual feed companies.

Water exchange: the water level is maintained at a depth of 1-1.3 m throughout culture period by pumping water into the pond from nearby creeks. Most ponds are not able to exchange their water on a regular basis due to their limited access to quality saltwater. However, some drainage from pond can be undertaken in case of very poor water quality or shrimp health conditions.

Aeration: one to three single horse power paddle wheel aerators are usually used, depending on farm size and stocking densities. The aerators typically operate for 8-12 hours per day during the entire culture period and create water current for the accumulation of wastes in the centre of the pond and to increase the dissolved oxygen in the water column. Aerators are placed 3 m away from the dykes and almost 40 m apart.

The brackish water is pumped into the pond through fine filtration systems up to a depth of 3-4 feet. The water is treated with chlorine at 20 ppm-30 ppm and left for one week. The pond water is also treated with minerals and probiotic yeasts before stocking.

Biosecurity: certain biosecurity measures are carried out like bird netting, crab fencing etc, but most farms lack proper biosecurity.

Stocking: quality L. vannamei post-larvae pl12 – PL16 are procured from shrimp hatcheries after quality and PCR tests. The post-larvae are transported from hatcheries to culture ponds by road and air, and should only be stocked after a proper acclimatisation process.

Stocking density: The stocking density of shrimp post-larvae is usually in the range of 70-100/m2 but can be as high as 120-150/m2.

| Stocking Density of PL | % of Pond |

|---|---|

| Below 50 No/M2 | 5% |

| PL 51-70 No/M2 | 25% |

| PL 71-100 No/M2 | 60% |

| PL 101-120 No/M2 | 5% |

| Above PL 121-150 No/M2 | 5% |

Feeding: all farms use formulated commercial pellets for routine feeding purposes. Most use a combination of broadcasting and check tray methods as feeding strategies, adjusting the levels regularly according to observations. On the whole they are fed four times a day, according to the recommendations of individual feed companies.

Water exchange: the water level is maintained at a depth of 1-1.3 m throughout culture period by pumping water into the pond from nearby creeks. Most ponds are not able to exchange their water on a regular basis due to their limited access to quality saltwater. However, some drainage from pond can be undertaken in case of very poor water quality or shrimp health conditions.

Aeration: one to three single horse power paddle wheel aerators are usually used, depending on farm size and stocking densities. The aerators typically operate for 8-12 hours per day during the entire culture period and create water current for the accumulation of wastes in the centre of the pond and to increase the dissolved oxygen in the water column. Aerators are placed 3 m away from the dykes and almost 40 m apart.

Water & soil treatments: After stocking, probiotics, minerals, zeolites, ammonia reducer compounds, dissolved oxygen (DO) enhancer compounds and disinfectants are widely used at regular intervals. The pond bottom sediment turns blacker with the increase of culture days and rate of feeding dose. The sludge formation is controlled by applying sludge digesting probiotic products from various commercial companies.

The various feed supplements are applied along with pellet feed for the promotion of growth, avoiding loose or soft shell, prevent diseases etc.

Application of home-made juice: A homemade juice is applied once in a week. 8 kg of sugarcane jiggery, 20 kg of rice bran, 32 kg of dolomite, 200 gm of yeast powder, 500 gm of curd are mixed thoroughly in an earthen tub and soaked for 1-2 days and applied to tank water @ 30 lt/tank to keep the tank environment at optimum level.

Water quality parameters: the major water parameters are measured and recorded daily or weekly with the help of field testing instruments and test kits. The major water quality parameters - salinity, dissolved oxygen, pH, temperature and total ammonia nitrogen (TAN) - are monitored at regular intervals. The major water parameters of most of ponds are in the following ranges:

| Water Parameters | Value Range |

|---|---|

| pH | 7.4 - 9.4 |

| Salinity (ppt) | 5.0 - 35.0 |

| Dissolved Oxygen (mg/lit) | 3.6 - 6.5 |

| Ammonia (ppm) | 0.1 - 2.4 |

| Temperature °C | 24.0 - 32.0 |

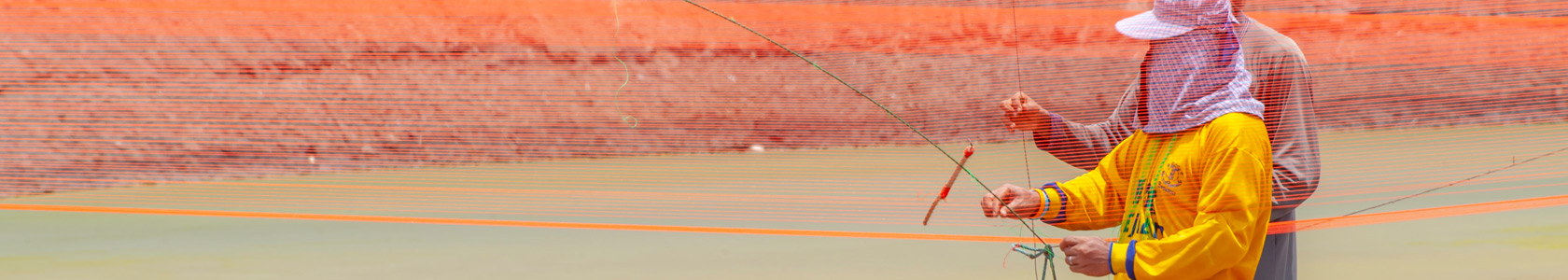

Sampling: Weekly sampling is very important to assess shrimp health, growth and survival.

Sampling is undertaken fortnightly at dawn, with cast net, after 60 DOC in most of ponds. Four to five hauls are made in each pond to assess survival, moulting stage, average body weight (ABW) and health.

Shrimp survival and growth rates in this region are impressive considering the dimensions of the ponds, stocking densities and lack of water exchange.

However, while presently these ponds are showing better than average results despite minimal biosecurity and water management more attention will be required in the future to ensure strict biosecurity and best management practice. It is also essential that extensive training programmes are offered to farmers to maintain the sustainability of the industry.